A simple & accurate solution to understanding water activity in organic, hygroscopic materials.

The problem: Most of us look at the our blue wheelie bins and wonder how they fill up so quickly with cans, tins, glass and plastics. Whilst most of these products are recyclable to an extent, a great deal of energy and resources are needed for this process and not all material is fully reusable or recyclable as we might think…

*Facts:

Plastic bottles – only 10 % of recyclable plastics are usable within the manufacture of PET bottles, most has to be virgin new plastic , due to quality and safety requirements.

However, other products may use recycled PET from bottles, such as furniture or even textiles. Since 2004, the global production of PET bottles has increased from 300 to 600 billion units per year, made mostly from virgin plastic materials.

In the UK alone, almost 5.9 billion aluminium drinks cans are manufactured each year with a 70% use of recycled materials. Aluminium is one of the most recyclable packaging materials available to us but requires significant energy for this process.

Around 700 billion glass bottles and jars are manufactured globally each year, using only 20% of recycled glass material or ‘cullet’ as it is known. Glass requires comparatively even greater amounts of energy to produce, process and mould

into containers and bottles. However, glass is generally about 70% recyclable for use in the manufacturing of other products, such as building insulation and aggregates.

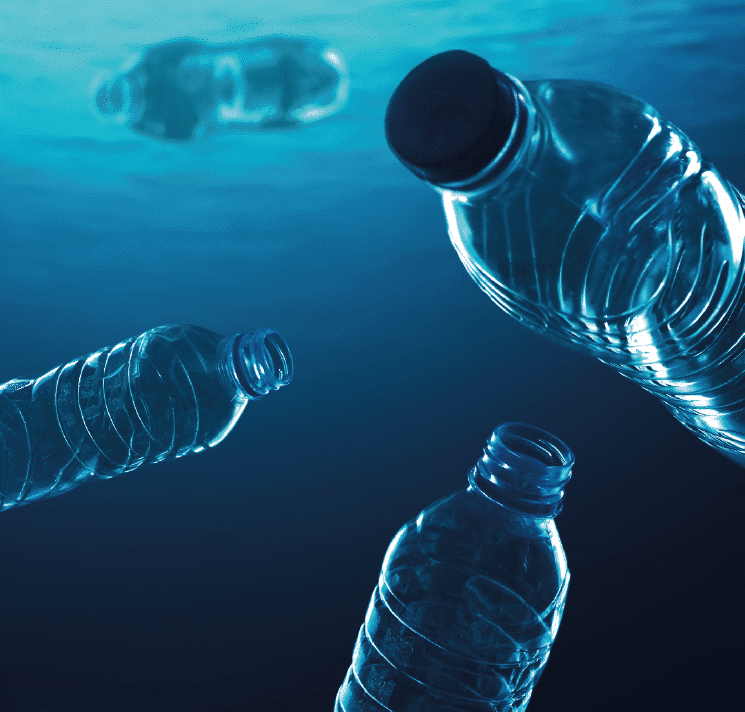

Plastic waste is by far the most harmful to the environment because it breaks down into micro beads and threatens wildlife and marine life. Glass and metals are generally inert materials which don’t have as much an impact on the environment as plastics do.

Plastics can be ingested into creatures and affect the food chain on land and marine.

How much of our waste ends up

in landfill?

Out of 26 million tonnes annually of UK waste from wheelie bins, only 12M is actually recycled, whereas the remainder goes into landfill or even gets sent to other countries like Malaysia, as a ‘dumping ground’ for payment in return.

The UK creates more plastic disposables per person than any other country as of 2023.

Where will it take us ?

By the year 2040, it is predicted that our oceans could be further polluted with a three-fold increase in plastic waste flowing into the oceans around the world, if we don’t find solutions to this problem.

Solutions in seaweed:

A leading UK company now manufactures packaging which is sourced from sustainable seaweed and is 100% biodegradable, as a green alternative to some of the plastics that are causing pollution problems.

Whilst seaweed grows naturally in abundance, seaweed farming can also have the benefit of absorbing CO2 from the environment to reduce greenhouse emissions.

Polymers can be extracted from seaweed and used to make materials that behave like plastic to make a wide range of packaging and can even be injection moulded

to produce biodegradable cutlery. Other sustainable materials like corn starch are also used in these kind of disposables but seaweed polymers benefit packaging materials with better properties such as stability and elasticity.

Fully biodegradable (and even edible) packaging capsules and cartons are being developed and filled with products such as: fast food, drinks, energy gels & hygiene products.

The Challeges

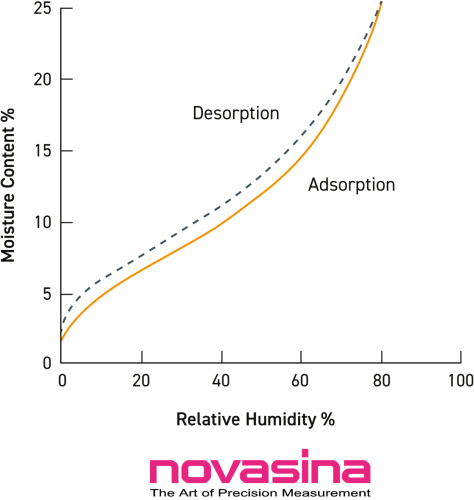

Organic materials like seaweed, that were once life, are absorbent to water unlike inorganics including metals, glass and plastics. In this respect, absorption (taking up water) or desorption (drying out) can occur in the air or when the packaging is in direct contact with the product (like a gel capsule) and could cause quality issues.

Solutions with water activity and relative humidity measurement:

It is the relative humidity of the air (%Rh), the relative humidity of the product (% ERH -equilibrium relative humidity) as well as the ERH% of the packaging which can all react with one another to create moisture migration and instability.

Furthermore, microbiological growth and product safety could also be impacted by these same factors.

Equilibrium relative humidity within a material is expressed as 0-100% ERH but is often referred to as Water activity (Aw) which is the same but recorded on a scale of 0-1 Aw units. Thus 50% ERH is 0.5 Aw units. Water activity is considered to be the

available water that is free to leave the product via the process of evaporation. It is this available water that influences microbial control and water migration to the air or surrounding packaging because it is effectively the humidity between the different layers or component parts and reaction to the environmental humidity which all try to balance with one another, or equilibrate.

How is water activity testing carried out?

The Novasina precision range of water activity meters are simple to use and calibrate: Samples of all types (granulate, liquid, paste, solid etc.) may be prepared into the small plastic dish and then placed into the chamber of the Labtouch aw meter. The START button is selected on the intuitive touch screen menu and an accurate reading is shown on the display within minutes.

Calibration is carried out similarly, but with reusable humidity salt tablets as samples, at intervals to suit the user.

Water activity can improve adable polymer packaging:

Quality of product + packaging, longer shelf-life, safer microbial growth & stability by a better understanding of the reaction to the humidity and temperature of the storage, transport and usage environment.